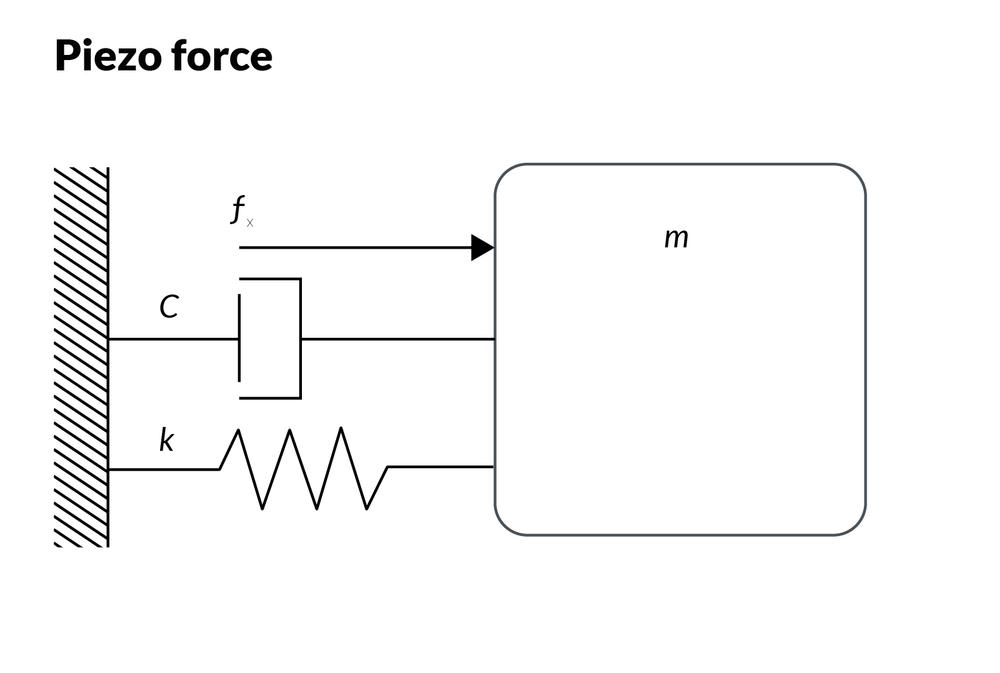

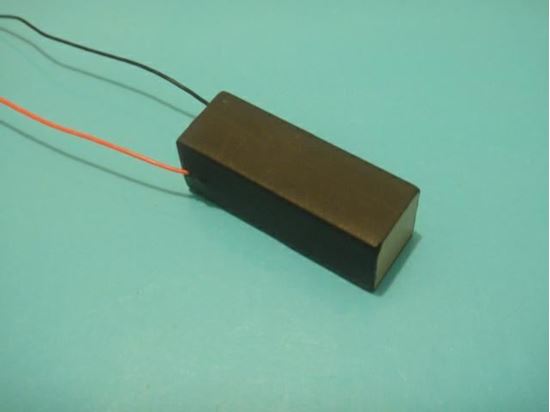

little or no outgassing or particle generation as flexure based designs have little or no friction and require no lubricationĭSM’s piezo-actuators harness the small precise amount of expansion generated by the piezoelectric effect to produce a wide range of actuator solutions.very high force per unit area (force and stroke directly scales with size).very high frequency response (bandwidth).low or zero power position hold capability.solid-state construction with zero backlash, stiction, or cogging.Even with the added mass and lower stiffness of an amplification mechanism, the natural frequency of an amplified piezo-actuator may be a few kiloHertz.Īdditionally, when designed and constructed properly, piezo-actuators can exhibit the following strengths. Therefore, natural frequency of a PZT stack may be several kiloHertz. Generally, the response time of a piezo-stack is limited by the speed of sound in the material. With proper system design, piezo-actuators hold the potential for high speed operation. When fabricating, measuring, or testing extremely small structures or features, piezo-actuators can provide very smooth and continuous motion over a range of a few microns to a few millimeters. For example, piezo-actuators excel in precision positioning applications where small, high-force moves are desirable. Given the relatively small displacement that a PZT stack can develop, piezo actuators have unique design considerations. PZT stacks expand in the column direction as represented in Figure 1. A monolithic stack of PZT layers and electrodes (called a PZT stack) is most often used in DSM’s piezo-actuators. For example, when actuated, a 1 mm thick layer of PZT will increase in thickness by one micron.

A typical value for length change might be 0.1 percent of the total material length in the direction of the applied field. The change in length is generally proportional to the field strength as applied via the device actuation voltage.

This “induced strain” or change in length occurs as electrical dipoles in the material rotate to align with an orientation that more closely aligns with the direction of the applied electric field. Piezoelectric materials exhibit an effect whereby they expand or contract in the presence of an applied electric field. Producing Displacement: DSM uses the term “piezo-actuator” for actuator or motion generating devices that use electro-expansive ceramic materials such as lead zirconate titanate (PZT), as the prime mover. Using the Piezoelectric Effect to Generate Motion and Force The very fast response times, wide operating bandwidth, and high specific force may be beneficial for applications in fluid valve control, optical scanning, vibration isolation, and precision machining. This property makes them useful in precision positioning and scanning systems. Piezo-actuators can produce smooth continuous motion with resolution levels at the nanometer and sub-nanometer level. The following information on piezo-actuator design and performance issues can be helpful when comparing piezoelectric-based actuators to more conventional electromagnetic actuators (solenoids, motors, voice-coils) and other “induced strain actuator” materials such as electrostrictive ceramic, magnetostrictive, and shape memory alloys.Īctuators based on piezoelectric ceramic material prime movers (or piezo-actuators) are finding broad acceptance in applications where precision motion and/or high frequency operation is required. Understanding the basic operating concepts behind piezo-actuators may also be beneficial to controlling and operating the piezo-actuators. Using piezo-actuators requires an understanding of actuator mechanical and electrical performance issues.

0 kommentar(er)

0 kommentar(er)